Product Description:

The KCF6052 capacitive liquid level sensor is specifically designed for measuring challenging environments such as those containing sewage, high viscosity fluids, or substances that may easily crystallize or adhere to the sensor. This sensor does not have any moving or elastic parts, which helps improve its impact resistance and reliability. This high-precision sensor offers good value for money and is ideal for replacing other level sensors such as radio frequency admittance, radar, ultrasonic, or magnetostrictive sensors to ensure accurate measurements of different types of media.

The core component of the KCF6052 capacitive liquid level sensor comprises advanced radio frequency capacitance detection circuitry. The circuitry is converted into a standard electrical signal through precise temperature compensation and linear correction by the sensor's internal processor. This product uses tomographic scanning technology to automatically detect changes in temperature and dielectric constant of the medium, automatically calibrating itself, and adapting to the measured medium. The sensor provides excellent super adaptability including anti-hanging, anti-condensation, and anti-bubble functionality. It is highly versatile and does not require frequent recalibration, making it suitable for use in various complex places with different measurement requirements.

The KCF6052 capacitive liquid level sensor is built to last, even in harsh environments with an IP68 protection rating. It is suitable for long-term and stable measurement in challenging environments.

Feature:

- Automatic adaptation, automatic calibration, long-term stable output of real height value.

- Anti-hanging, anti-condensation, anti-bubble and other anti-fouling ability is super strong.

- Simple structure, no moving parts, high reliability, less maintenance.

- A variety of signal outputs are available for easy access to different systems.

- It is not affected by the temperature, specific gravity, pressure and other factors of the measured liquid.

- The highest temperature resistance is ≤250℃, the highest pressure resistance is ≤4MPa, and the service life is long.

- Good sealing performance, protection grade IP68 (except 6052).

- Perfect over-current, over-voltage, power polarity protection measures.

- Measuring cycle: 0.5 seconds

- Long-term stability: ≤0.1%FS/year

- Temperature drift: ≤0.02%FS/℃ (in the range of -40℃~+80℃)

- Measurement accuracy:

When the measurement range is within 300mm, the absolute error is within ±3mm (including 3mm);

When the measurement range is 300-700mm, the accuracy level is 1.0;

When the measurement range is 700-2000mm, the accuracy level is 0.5;

Technical Parameters:

●Detection range: 0.01~30 m

●Accuracy: level 0.2, level 0.5

●Pressure range: -0.1MPa~32MPa

●Probe temperature: -50~250 ℃

●Ambient temperature: -20~60 ℃

●Storage Temperature: -55℃~+125 ℃

●Output signal: 4~20mA,4 ~ 20mA with HART communication/485/CAN bus communication

●Supply voltage: 12~28VDC (should be powered by the safety barrier)

●Fixation: Screw mounting M20×1.5,M27×2,

Flange mounting DN25,DN40,DN50.Special specifications can be customized

●Wetted material: 316 Stainless steel,1Gr18Ni19Tior or PTFE

●Long-term stability: ≤0.2%FS/Year,

●Temperature drift:≤0.02%FS/℃ ( range of 0~70℃)

●Explosion levels: Intrinsically Safe ExiraⅡC T6, Flameproof Ext II C T5

●Protection:IP67

●Intrinsically Safe parameters:Ui:28VDC,Ii:93mA, Pi: 0.65W, Ci: 0.042uf, Li: 0mH

Installation

Before installation, you must check the product model, technical parameters, installation port, and application environment in detail to ensure that the on-site sensor matches the installation environment. If you find any problems, contact the sales staff as soon as possible to confirm subsequent installation matters or return and exchange matters, so as to avoid damage caused by wrong use. Inaccurate measurement or product damage occurs.

Warning: It is forbidden to install live, disassemble, collide, drop, or hit hard

The liquid level sensor has a variety of installation and fixing methods to adapt to different site conditions. The specific installation is as follows.

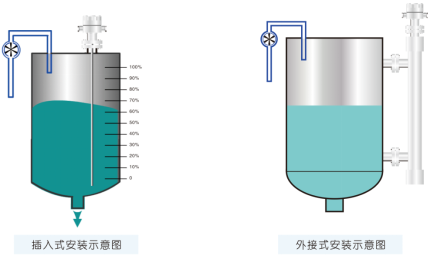

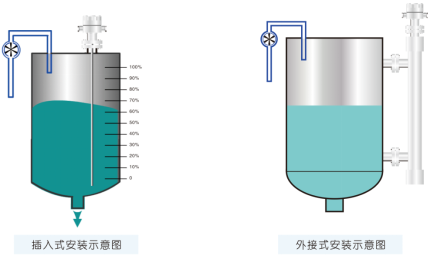

1. The sensor is installed on a sealed metal container, which can be connected by flange or thread. When the measuring medium has no stirring, liquid impact, violent swing, etc., it can be installed in a plug-in type, as shown in the figure below: plug-in type installation

2. The sensor is installed on the container where there is stirring, liquid impact, violent swing, etc. in the measurement medium. The sensor can be installed with a connected pipe outside the container through a flange or threaded connection, as shown in the figure below: external installation

3. The measurement medium has stirring, liquid impact, violent swing, etc., and the container does not have the conditions for external installation of connecting pipes. When plug-in installation must be used, the sensor must be equipped with a protective tube. The measuring range exceeds 1000mm, and the container must be reserved. Or install a fixed bracket to ensure that the sensor is damaged due to violent impact of liquid.

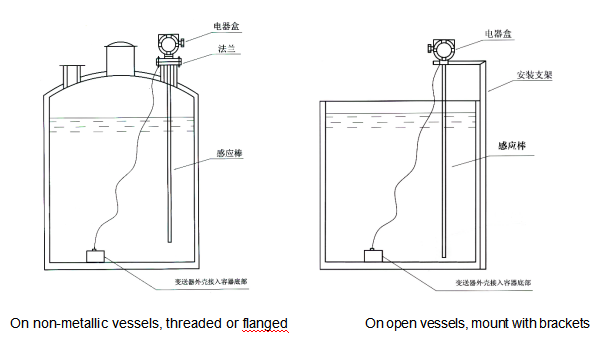

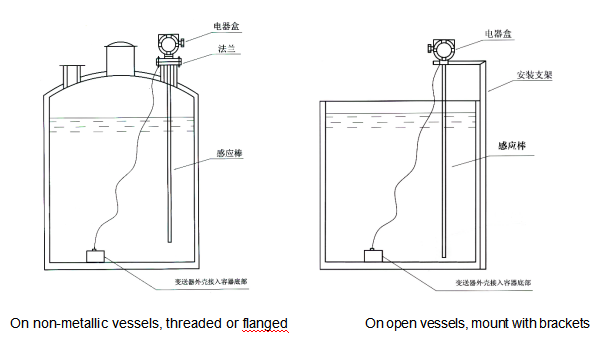

4. The sensor can be connected by flange or thread when the non-metallic container or the installation surface is insulated from the inner edge of the container. The sensor option must use an auxiliary electrode or a protective sleeve structure. If the required structure is not adopted, the normal operation of the sensor cannot be guaranteed. Output, you need to install the auxiliary electrode yourself (use one end of the metal wire to connect the sensor shell/flange, and add a counterweight to the bottom of the container at the other end, and reserve a certain length for the wire to avoid damaging the wire), as shown in the figure below: On a non-metallic container , threaded or flange mounted

5. The sensor can be connected to the mounting bracket by flange or thread on the open container. The sensor option must use an auxiliary electrode or a protective sleeve structure. If the required structure is not adopted, the normal working output of the sensor cannot be guaranteed, and an auxiliary device needs to be installed by itself. Electrodes (connect one end of the metal wire to the sensor shell/flange, add a counterweight object to the bottom of the container at one end, reserve a certain length for the wire to avoid damage to the wire), as shown in the figure below: on the open container, install the bracket (the installation position is at a distance from The distance from the pool wall must be greater than 10CM, otherwise the measurement will be inaccurate.

Applications:

One of the key features of the Kacise Fluid Level Meter is its capacitive liquid level sensing technology, which ensures high accuracy and stability in harsh environments. The temperature drift of the product is ≤0.02%FS/℃, making it highly resistant to temperature changes ranging from 0 to 70℃. The long-term stability of the product is also remarkable, with ≤0.2%FS/Year, ensuring that the product can be used for a long time without the need for frequent calibration.

The Kacise Fluid Level Meter is manufactured in China (Mainland) and has a minimum order quantity of 2. It is packaged in cartons and can be delivered within 5 working days after payment has been made. Speaking of payment, 100% payment in advance is required when placing an order.

The product can operate normally in an ambient temperature range of -20~60 ℃, and can be stored in a temperature range of -55℃~+125 ℃, making it suitable for use in various environments.

In summary, the Kacise Fluid Level Meter (Model Number: KCF6052-1-625mm) is a capacitive oil level sensor suitable for measuring liquid levels in trucks and industrial tanks. It is characterized by its high accuracy, stability, and durability, making it an ideal choice for various applications.

Support and Services:

The Fluid Level Meter product technical support and services include:

- Installation guidance and support

- Product training and education

- Maintenance and repair services

- Product troubleshooting

- Remote technical support

- Product updates and upgrades

Packing and Shipping:

Product Packaging:

The Fluid Level Meter product will be packaged in a sturdy cardboard box with foam inserts to protect the device during shipping. The product will be wrapped in bubble wrap to ensure further protection during shipping.

Shipping:

The Fluid Level Meter product will be shipped via standard ground shipping. Customers can expect to receive their orders within 5-7 business days. Expedited shipping options are available at an additional cost.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!